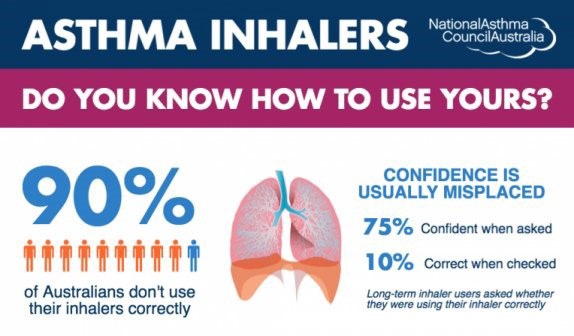

As discussed in a number of the National Asthma Council Australia's fact sheets (below), 90% of Australians don't know how to use their inhaler correctly. The concept behind this 3D printed prototype is to reduce some of the common problems people have, as well as extending an inhalers life cycle.

One of the biggest problems when using a puffer is not inhaling for long enough, which results in a smaller than recommended dosage being consumed. To combat this, when the user pushes the canister down during use, a vibration motor on a time delay is triggered. After 3 seconds the vibration motor runs to communicate to the user that they can stop inhaling. While the current prototype uses vibration as a method of communicating, there are plans to target the puffer towards children learning to use an inhaler, with communication being extended to sounds and/or lights. The hope is that not only will technique be improved, but also kids might feel less embarrassed to use their inhaler around others.

The inhaler concept is also designed to reduce waste. Current inhalers are used a specific number of times before the canister and the inhaler are thrown away. By increasing the value of the inhaler through technology (vibration, sounds and lights) and selling canisters separately, the user will place higher significance on the item and use it multiple times before replacing

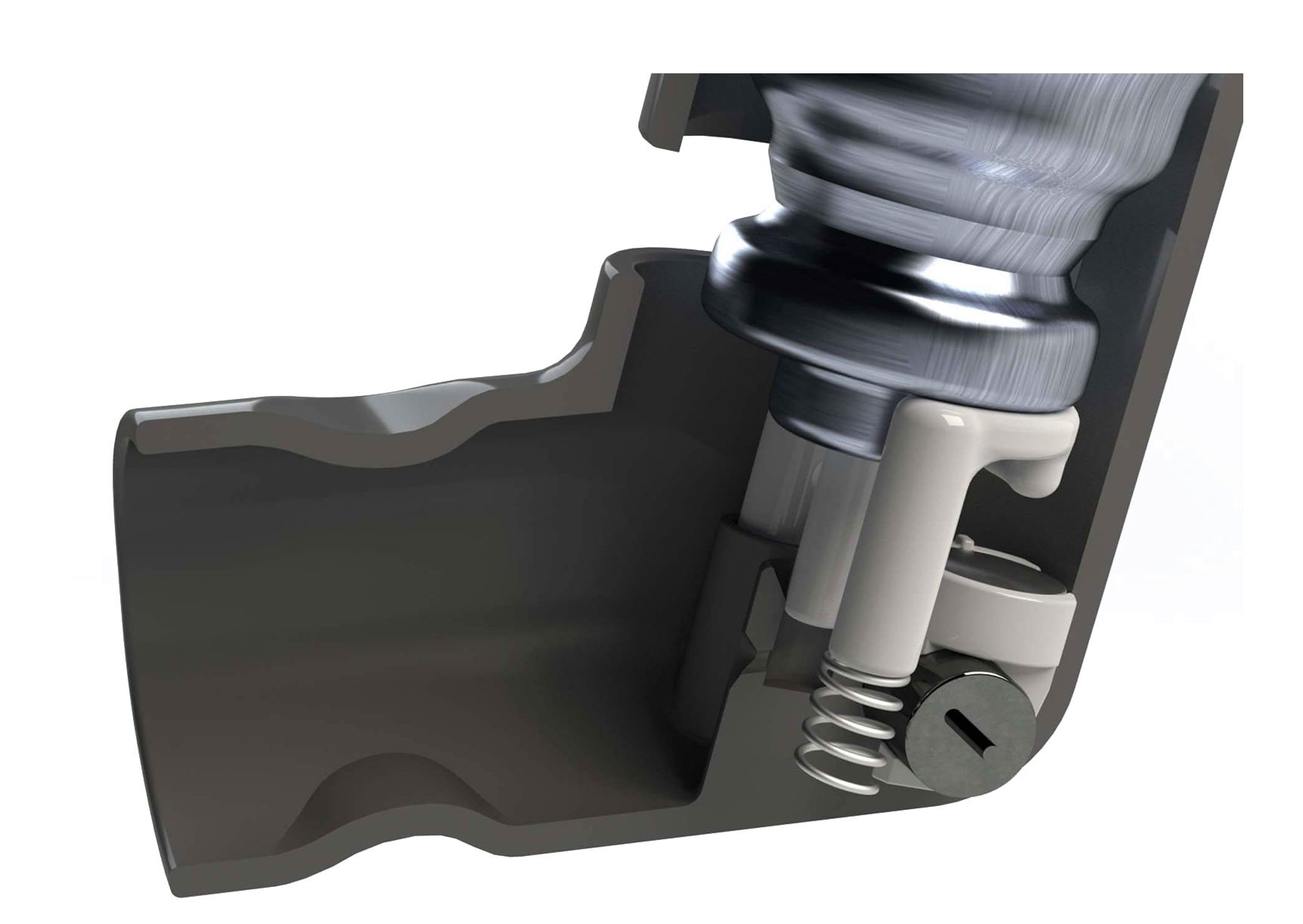

These high quality renders show the 3D model before printing, with a cutaway view clearly displaying the technical package (battery and holder, vibration motor, support and springs)