HOOK CARTON RE-DESIGN

FINAL PRODUCT

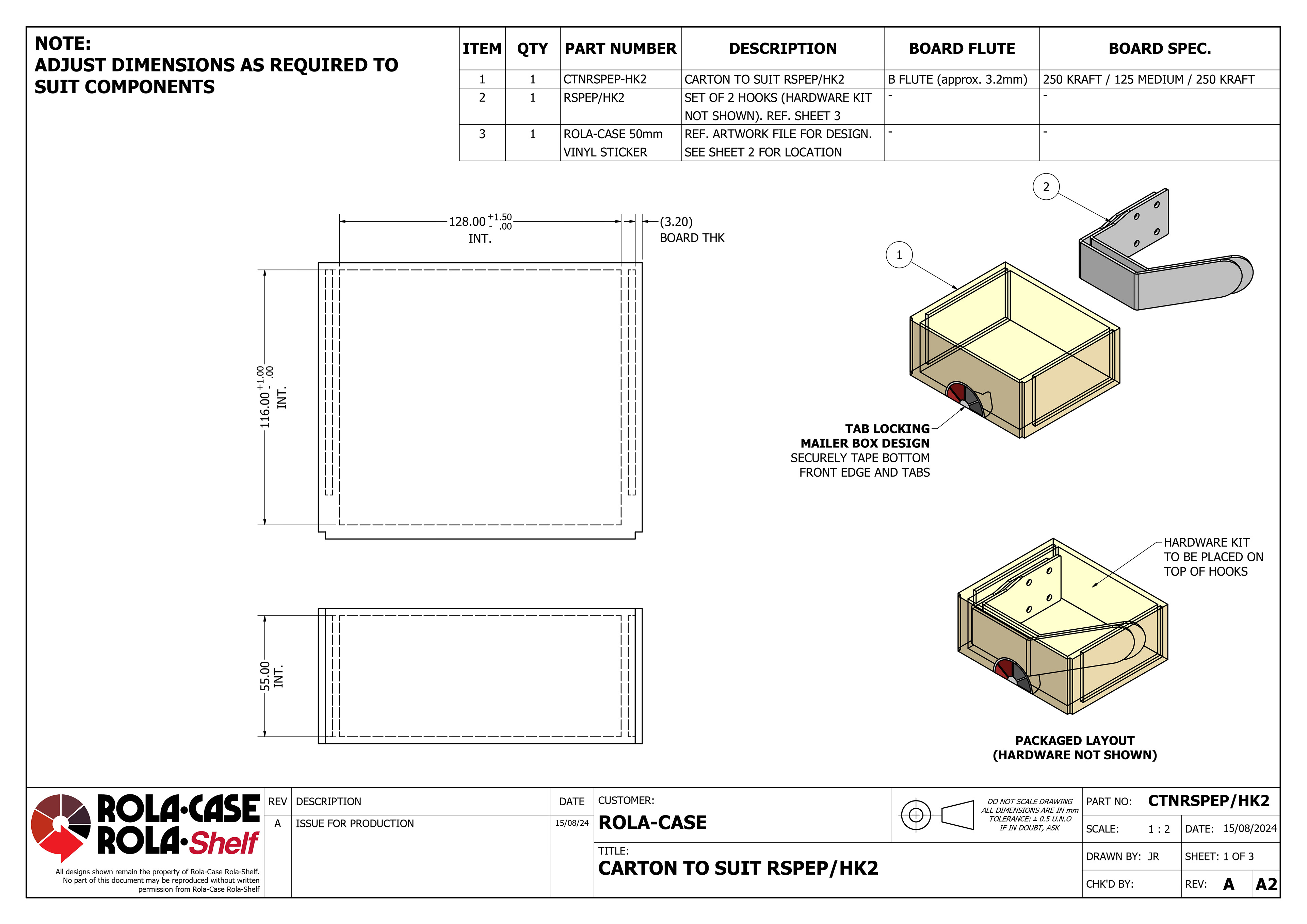

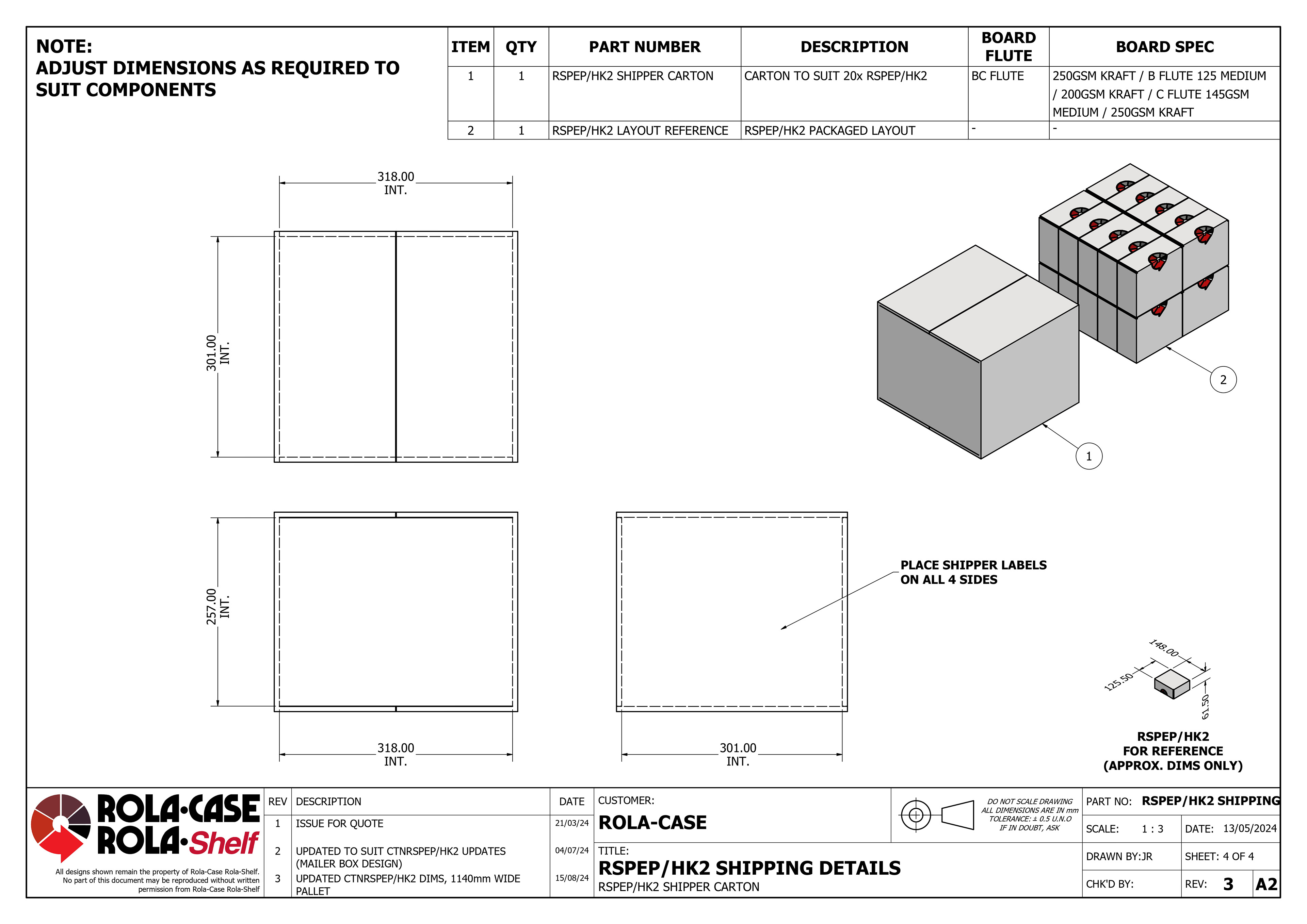

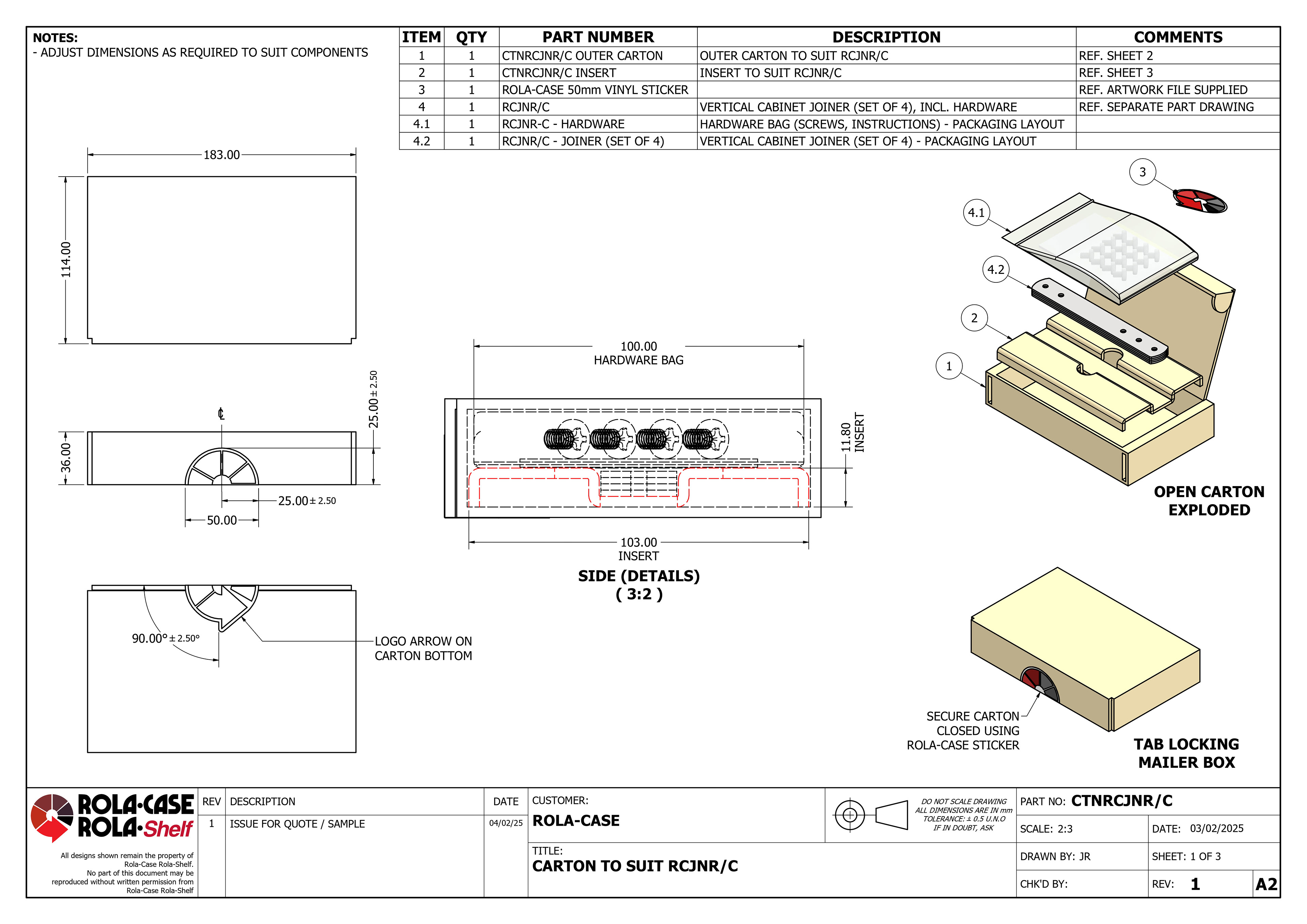

SPECIFICATION DRAWINGS

DESIGN PROCESS

PREVIOUS DESIGN

Regular flap carton, with basic artwork and poorly fitting contents.

Corrugated board quality was not suitable, splitting at the corner when trying to close.

Regular flap carton, with basic artwork and poorly fitting contents.

Corrugated board quality was not suitable, splitting at the corner when trying to close.

UPDATED DESIGN PROTOTYPE

Mailer-box carton with dimensions optimized to suit the best part layout for reduced impact during transit. Paper prototype of the packaging logo sticker used to get the full customer experience.

Final design with artwork and stickers shown above.

Mailer-box carton with dimensions optimized to suit the best part layout for reduced impact during transit. Paper prototype of the packaging logo sticker used to get the full customer experience.

Final design with artwork and stickers shown above.

PACKAGING LOGO STICKER

FINAL PRODUCT

SPECIFICATION DRAWINGS

DESIGN REVIEW - ANGLE INSERT

FIRST PROTOTYPE:

Due to the shape of the part, large areas of the carton are unfilled and unsupported, resulting in a weak and warping final product.

Due to the shape of the part, large areas of the carton are unfilled and unsupported, resulting in a weak and warping final product.

RESOLUTION:

An insert is required to fill the empty voids of the carton, to create a more rigid design.

A folded corrugated board insert was prototyped in-house (below), before moving to a honeycomb board design, which was cheaper, easier and more effective.

An insert is required to fill the empty voids of the carton, to create a more rigid design.

A folded corrugated board insert was prototyped in-house (below), before moving to a honeycomb board design, which was cheaper, easier and more effective.

PAPER PROTOTYPING

SPECIFICATION DRAWING

FINAL PRODUCT

DESIGN REVIEW - CHANNEL INSERT

FIRST PROTOTYPE

Internal folded corrugated board divider to protect parts during transport, and to fill the outer carton appropriately (larger accessories not shown).

The design allowed too much flexibility, resulting in the carton feeling weak.

Internal folded corrugated board divider to protect parts during transport, and to fill the outer carton appropriately (larger accessories not shown).

The design allowed too much flexibility, resulting in the carton feeling weak.

SECOND PROTOTYPE

Honeycomb board insert used to separate the parts enough to fill the outer carton, protecting the parts and creating a more rigid configuration.

Honeycomb board insert used to separate the parts enough to fill the outer carton, protecting the parts and creating a more rigid configuration.

SPECIFICATION DRAWING

FINAL PRODUCT